今天是2025年7月14日 星期一,歡迎光臨本站

高潔凈全自動離心機 |

PGZW1250N

|

|

|

PGZW1250N高潔凈型全自動離心機是一種立式、小刮刀卸料、自動間歇操作過濾式離心機,可通過自動或手動方式進行周期性循環操作。該離心機最初是為了滿足分離成品味精所需的高潔凈度、高脫水速度要求而設計,是味精行業的關鍵設備之一,除了符合高標準衛生要求、國家GMP要求之外,獨特閉合罩設計還能有效防護出料不受污染,廣泛應用于結晶型物料及對出料潔凈度要求高的場合。

|

PGZW1250N automatic self-cleaning centrifuge for MSG discharges by small scraper,operates intermittently.It works cyclic automatically or manually.PGZ1250N designed originally for MSG industry,satisfied the requirements of high cleanliness and high running speed.Wonderful enclosure design protect MSG product free from contamination.This model widely used in deal with crystalline material and occasions with high cleanliness demand.

|

◎工作原理 |

|

|

| 待分離物料由進料管進入高速旋轉的離心機轉鼓,在離心力場的作用下,均布在轉鼓內壁的濾布上,進行過濾分離。分離過程中液相透過固相物料、濾布的縫隙和轉鼓壁上的小孔,從底盤的出液管流出;而固相物料則被截留在轉鼓壁內。進料及分離過程中,閉合罩始終與轉鼓底部緊密接觸,防止料液進入下料口。當達到分離要求后,閉合罩上升,刮刀機構開始卸料,料渣從出渣口排出。 |

Material comes into rotating drum trough feed tube,centrifugal force field makes it spread evenly on filter cloth of interior wall.During separation process,liquid trough gap within solid phase and filter cloth also holes of drum wall,discharges by outlet.While solid material retained within drum wall.In the process of feeding and separating,enclosure compactly combined with drum bottom,keep liquid material away from outlet.After separation,enclosure rises up,scraper unit discharges,residues discharge from outlet. |

◎主要特點 |

|

|

| 1、整機運轉平穩、噪音低、自動化程度高、操作靈活方便,勞動強度低。 2、采用變頻+PLC可編程控制系統,啟動平穩,通過程序設定實現自動化,能耗或回饋制動。 3、采用三相交流變頻調速異步電機驅動,在周期自動循環操作中,變頻無極調速可以最大限度地滿足低速進料、高速分離、低速卸料各工序對轉速的要求。根據物料性能的變化可以提供相應的轉速點實現最優化的操作。 4、無人看護,實現自動監測與保護。具有轉速檢測、料層探測、過振動保護、電機過載過熱保護、刮刀旋轉升降機械電氣雙重聯鎖保護等多項功能。 5、獨有內部閉合罩結構,確保工作過程中卸料口不受原液的污染,保證分離后物料的潔凈度。 |

1) Running stably,low noise,highly-automatized,easy handle and low labour intensity.

|

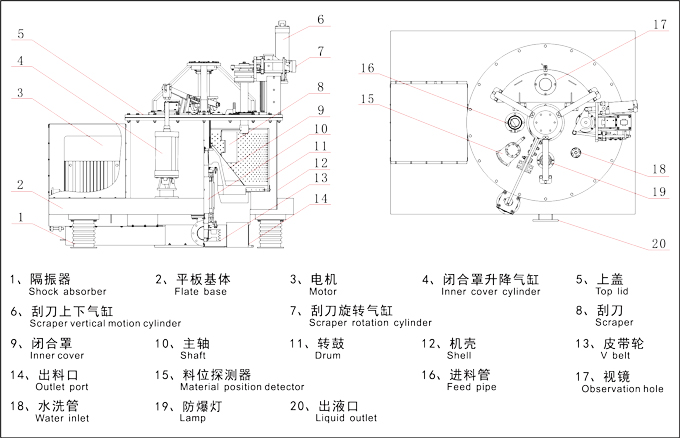

◎結構示意圖(Structure schematic diagram)

◎主要材料 |

◎Composition of critical parts |

|

|

1、平板為Q235A包襯不銹鋼。 |

1) Flat plate is made of Q235A carbon steel coated by stainless steel. 5) Scraper blade and shaft is made of SUS304 stainless steel. |

◎結構與配置(Structure and configuration)

|

項目(Item)

|

標準(Ordinary )

|

可選(Alternatives)

|

|

整機結構

(Whole machine set)

|

平板式結構

Flat plate

|

|

|

轉鼓與物料接觸部分的材質

(Drum contact with material part’s composition)

|

SUS304不銹鋼

SUS304 stainless steel

|

SUS316、316L、321不銹鋼、鈦材、襯塑、襯HALAR、襯膠等

Stainless steel:SUS316,SUS316L,SUS321;titanium;lining plastic;lining HALAR;lining rubber;etc.

|

|

上蓋結構

(Top lid)

|

平蓋

Flat lid

|

|

|

上蓋附件

(Top lid belongings)

|

進料管、水洗管、視鏡、防爆燈、刮刀裝置、料位探測器、人孔蓋

Feed tube,washing tube,observation hole,explosion-proof lamp,scraper unit,material position detecto and manhole

|

|

|

開蓋方式

(Lid opening)

|

人工

manual

|

|

|

布料方式

(Distribution method)

|

側向布料

Side distribution

|

|

|

電機種類

(Motor type)

|

變頻電機

frequency-alterable

|

普通電機、防爆電機、節能電機

Without frequency adjusting,explosion-proof or energy saving

|

|

制動方式

(Braking method)

|

能耗制動

Dynamic braking

|

回饋制動

Feedback braking

|

|

操控系統

(Controlling system)

|

變頻+PLC+HMI人機界面

frequency-alterable+PLC+HMI

|

|

|

安全防護(Safety technologies)

|

振動保護、電機防護罩、過載過熱保護、刮刀原位保護、刮刀旋轉與升降機械電氣雙重聯鎖保護

Over vibration,motor shield,overload,overheat,scraper in situ,scraper turning and lifting machinery electric dual control

|

轉速顯示、防爆裝置、在線含氧檢測充氮保護系統

Speed display,explosion-proof unit,oxygen detection and nitrogen protection online system

|

|

卸料方式

(Discharge method)

|

氣動刮刀

Pneumatic scraper

|

|

|

清潔處理

(Cleaning)

|

轉鼓水洗清潔、物料水洗清潔

Washing

|

在線清洗結構、高壓氣體反吹系統 Online washing structure,high pressure air back flushing system |

|

三角皮帶

(Triangular belt)

|

普通三角皮帶

Ordinary

|

防靜電三角皮帶

Static proof

|

|

其他

(Others)

|

|

其他配置要求

|

◎技術參數(Technical parameters)

|

轉鼓直徑

Drum D

|

轉鼓高度

Drum H

|

轉鼓轉速

Drum speed

|

分離因數

Separation factor

|

最大容積

Maximum volumn

|

最大裝料量

Maximum

load |

電機功率

Motor power

|

重量

Weight

|

外形尺寸

Dimensions

|

|

mm

|

mm

|

r/min

|

|

L

|

Kg

|

KW

|

Kg

|

mm

|

|

1250

|

600

|

0-1000

|

0-698

|

355

|

480

|

37

|

6000

|

2420×1800×2850

|